How to Store and Handle Lumber on Industrial Job Sites

Because twisted boards make twisted

timelines—and OSHA inspectors don’t laugh at “creative stacking.”

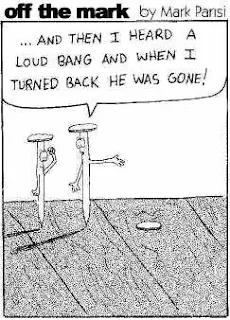

Don’t Let Your Lumber Go Lame

Picture this: You’ve

just dropped serious cash on high-grade lumber for a job already tighter than

your foreman’s schedule. But instead of treating it like the backbone of your

build, your crew stacks it like firewood for the company campout. A few days

later, it’s warped, soaked, sprouting mold—and here comes an OSHA inspector

with a clipboard and a permanent frown.

This isn’t rare.

According to the American Wood Council, up to 15% of wood materials are lost to

poor handling and storage. That’s not just bad luck—that’s bad planning. It’s

15 boards out of every 100 turning into mulch, bonfire fuel, or lawsuit fodder.

Whether you’re

building a distribution center, a factory, or a top-secret bunker with

biometric forklift access, handling your lumber right can save time, money, and

your reputation.

Rule

#1: Lumber Hates Water (and It Holds a Grudge)

Water is wood’s

worst frenemy. A little moisture and your lumber swells. Let it dry out, and it

doesn’t politely return to form—it twists, bows, and cracks like it’s trying to

escape.

Let it soak too long

and you’ve got mold, mildew, and rot—plus a new ecosystem for local wildlife.

Calumet

Tips:

- Keep lumber at least 6 inches off

the ground. Use dunnage, blocks, or racks—just don’t let your investment

lounge in the mud.

- Skip the plastic tarps. They trap

humidity. Go with breathable, UV-resistant covers made for construction.

- Let it breathe. Use stickers

(spacers, not emojis) to create airflow between layers.

- Store smart. Stay away from

low-lying or wet zones unless you're building a lumber swamp.

If you’re in a rainy

area, slap together a temp shelter. Doesn’t need to be pretty—just dry.

Don’t Let Gravity Win: Stack Like You Mean It

Even the straightest

boards will warp if you stack them like a drunken game of Jenga. Gravity

doesn't care about your budget—it just wants your stack to fail.

Nothing brings out

an OSHA inspector faster than a wobbling pile of timber leaning into a forklift

path.

Calumet

Tips:

- Stack by size and length. Mixing

8s with 16s creates stress points that could twist steel.

- Use stickers between layers.

Evenly spaced, consistent thickness—don’t cut corners.

- Keep it low and wide. Think

bunker, not tower.

- Label clearly. Know what’s what

and where it is. It beats playing hide and seek with your inventory.

We bundle and

organize lumber before it hits your site, so even Steve—who once tried to move

a 1,500 lb bunk with a pallet jack and a dream—can’t mess it up.

Sunburn

Isn’t Just for Humans

After moisture, UV

rays are your next biggest threat. The sun breaks down wood fibers faster than

you can say “change order,” causing surface damage, fading, cracking, and

all-around sadness.

Leave lumber out too

long and it turns into splintered toast. This hits engineered wood and OSB

especially hard—some of it can degrade within days.

Calumet

Tips:

- Use UV-resistant covers. Not

painter’s plastic—real lumber-grade tarps.

- Prioritize the vulnerable stuff.

OSB, treated, and engineered wood deserve the VIP treatment.

- Rotate your stacks. A weekly flip

keeps boards evenly exposed and avoids the “crispy side” dilemma.

You’re building

structures, not toasting marshmallows—shade that wood.

Measure Twice, Store Once

Ordering too much

lumber “just in case” is how you end up with a squirrel hotel next to your

rebar. Extra material sounds smart—until you’re navigating a maze of unused

stacks while trying not to trip over a 4x4.

Calumet

Tips:

- Schedule phased deliveries. Don’t

store three months of material on-site when the slab’s not even poured.

- Set designated zones. Keep stacks

near the action, but out of the way.

- Track what’s coming and going.

Even a dry erase board helps. You don’t need a database—just eyes on your

assets.

Our just-in-time

delivery service keeps your site clean, productive, and rodent-free.

Lift

with Your Legs, Not Your Ego

Lumber looks

harmless—until you’re mid-carry and it turns into a battering ram. Improper

handling doesn’t just tweak backs, it gouges boards, splinters edges, and racks

up reorders.

Calumet

Tips:

- Train your crew. Even seasoned

pros fall into bad habits. Refresh them often.

- Use the right gear. Dollies,

forklifts, cranes—they exist for a reason.

- Don’t drag. Boards that slide

over concrete end up damaged and moisture-prone.

That 2x12 may still

be usable after being dropped—but it won’t frame anything square. Protect your

materials and your crew.

Good Wood = Good Work

Storing and handling

lumber correctly won’t get you a gold star or a standing ovation—but it will

keep your project on track and your wallet intact.

Every twisted board

adds delays, costs money, and earns you a pointed look from your GF—or worse, a

clipboard-wielding OSHA inspector who hasn't smiled since the Reagan

administration.

At Calumet Lumber,

we don’t just deliver lumber—we deliver peace of mind. We’ve seen what happens

when good wood goes bad. We’ve seen what happens when Steve panics and staples

a checklist to his forehead at the first sight of a safety audit.

Want to avoid moldy

stacks, twisted piles, or impromptu OSHA comedy hours? Call us before 3:55 P.M.

As long as it’s not your head getting stapled, it’s worth it.

.png)

.png)

No comments:

Post a Comment