May the Compliance Be With You

A Star Wars Guide to Avoiding OSHA Violations

(With Help from Calumet

Lumber, of Course)

A

long time ago, in a galaxy not so far away—okay, it was actually just a

construction site in the Da Region—there was a growing rebellion against the

Empire of OSHA. Hard hats were worn sometimes, ladders

doubled as scaffolding, and “PPE” sounded more like a new kind of sandwich than

life-saving gear.

But

then came the inspections. The citations. The safety meetings that felt like

Sith torture. And just like that, the jobsite Wild West became a battlefield of

regulations, clipboards, and very serious men in very official vests.

Let’s

pause and talk about the Empire itself—OSHA. That’s the Occupational Safety and Health Administration,

and while the name sounds about as thrilling as reading blueprints in Huttese,

their job is simple: keep you

alive while you work. They set and enforce safety

standards, make surprise visits to job sites, and issue fines when things get

sketchy. If your site is a mess, your scaffolding’s a death trap, or someone’s

cutting rebar in flip-flops—OSHA’s the one bringing the hammer down (and not

the framing kind).

Staying OSHA-compliant can feel like trying to

land an X-Wing in a Tatooine dust storm—confusing, high-stakes, and full of

unexpected hazards. But fear not. Calumet

Lumber is here to help you navigate the Imperial

codebook and build like a Jedi—not a Jawa with a broken ladder.

Whether you're slinging two-by-fours or commanding

a whole crew of clones (contractors), this guide is your blueprint to avoiding

violations, protecting your team, and maybe even having a little fun along the

way.

Grab your saber—er, toolbelt—and let’s build a

safer galaxy, one OSHA-approved plank at a time.

The

Unsung Heroes: Your Safety Coordinator and Safety Team

If OSHA is the Empire laying down the

law, then your Safety Coordinator and their crew are the Jedi Council—equal

parts wisdom, vigilance, and laser-focus on keeping your site from becoming

ground zero for an OSHA nightmare.

These folks don’t just walk the

walk—they train, study, and prep like they’re about to lead troops into battle

(because, honestly, they are). Here’s what sets them apart:

Training

That Rivals Jedi Knight Trials

Your safety coordinator isn’t just

someone who likes checklists. They’ve put in hours—often years—of

specialized training that includes:

- OSHA 10/30 Certification

(sometimes both)

- CPR and First Aid certification

- Hazard Communication (HAZCOM)

training

- Scaffold, ladder, and fall

protection safety standards

- Forklift and equipment operation

safety

- Incident investigation and root

cause analysis

- Site-specific training based on

your crew's work environment

They’re constantly attending refresher

courses, webinars, toolbox talks, and safety conferences to stay ahead of the

ever-evolving rulebook. While the rest of us are catching up on weekend

football, they’re reviewing new compliance regs over their morning coffee.

A

Day in the Life of a Safety Jedi

They’re not just walking around

pointing at trip hazards. Their daily grind might include:

- Inspecting ladders, scaffolding,

and guardrails

- Conducting morning safety

briefings

- Reviewing jobsite setups for

proper signage and access

- Checking PPE compliance (and

catching the guy who always forgets his glasses)

- Updating SDS binders and

emergency plans

- Keeping records so pristine

they’d make an Imperial officer sweat

And when something goes sideways?

They're first on scene, documenting every detail faster than a protocol droid

under pressure, guiding first response, and managing the fallout so the site

doesn’t spiral into chaos.

Why

the Safety Team Matters

On larger jobs, a solo safety

coordinator often works with a safety team—a crew of trained individuals who

monitor different areas, rotate inspections, run safety drills, and mentor new

hires. They’re the first to adopt new safety tech, the last to leave a

walkthrough, and the reason your crew goes home in one piece.

Let’s be real: these people are the reason

your company hasn’t made the news for all the wrong reasons. Give them respect,

give them resources, and maybe even buy them lunch once in a while. They’ve

earned it.

These

Aren’t the Planks You’re Looking For

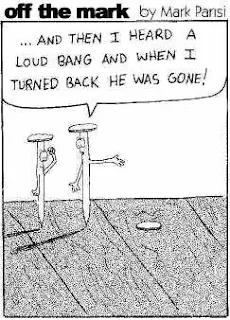

Let’s talk scaffolding. We’ve all seen the guy who thinks a piece of ¾"

CDX plywood makes a great work platform. Spoiler alert: it doesn’t. That’s how

you end up in an OSHA report titled “Man Falls After Trusting

Sketchy Plank—Film at 11.”

Use

OSHA Plank. It’s literally in the name, folks. It’s graded. It’s stamped. It

won’t crack like Anakin at Jedi therapy.

Not

sure what makes an OSHA plank actually OSHA-approved? Or wondering why SPF and

Common Hardwood are not interchangeable with the fate of your kneecaps? Go back

and check out my blog post “Plankvengers:

Endgrain — A Marvel-Lumber Mashup You Didn't Know You Needed.”

It breaks down lumber types with more action than a Hulk smash on a jobsite.

Need

it fast? Calumet Lumber stocks it and delivers it. We won’t judge your

last-minute call. We’ve all procrastinated, but let’s not make safety one of

those things.

Hard

Hats: Not Just for Stormtroopers

Yeah, Stormtroopers might be terrible shots, but at least they wear protection.

On Earth, falling hammers and flying debris are way more accurate. And they

don’t care if you’re wearing a Carhartt hoodie—your skull needs a helmet.

Pro tip: Calumet carries gear that keeps your head

in the game—and not splattered on the ground like a poorly piloted X-Wing.

I Find Your

Lack of Guardrails… Disturbing

We love a good, elevated platform as much as the next Jedi, but if your

mezzanine looks like the edge of the Sarlacc Pit, put up a guardrail.

OSHA doesn’t care if it “slows you down” or

“messes with the aesthetic.” It’s a long way down, and you’re not Boba Fett.

At Calumet, we’ve got the lumber and materials to

build safe, code-compliant railings faster than the Millennium Falcon in a

Kessel Run.

The PPE Awakens

PPE isn’t just a buzzword—it’s your armor. Eye protection, hearing protection,

gloves, high-vis vests… It’s not cosplay. It’s literally the difference between

getting home with all ten fingers or having to explain to your spouse why you

now type like C-3PO with a software bug.

Calumet has vendor connections to get you suited

up and ready to work like the jobsite Jedi you are—not a rogue Sith apprentice

trying to impress OSHA with their “creative” footwear choices.

Help Me,

Calumet Lumber, You’re My Only Hope

Whether you’re new to construction, managing a crew of clones (er,

contractors), or just trying to not get written up again, Calumet has your

back. Our team has seen it all, stocked it all, and probably delivered it to a

jobsite where a guy named “Chewie” was actually running the forklift.

If you need OSHA-approved planking, safety gear,

or just someone to talk you down when you’re about to use a folding chair as a

step ladder—call us. We’ve been fighting the dark side of sketchy job sites

since before OSHA was even born.

Tales

from the Dark Side — Real OSHA Violations That Hit Harder Than a Stormtrooper

Headbutt

Even Jedi need a reality check

sometimes. It’s easy to think, “That won’t happen to us,” until the job site

becomes a headline—and not the good kind. These are just a few real-world

examples of what happens when the Force (aka OSHA compliance) is ignored:

- BP Whiting Refinery (Whiting, IN): In 2006, BP got hit with $384,000

in fines after Indiana regulators found multiple safety violations. The

Empire (er, OSHA) doesn’t mess around when it comes to refinery safety.

- U.S. Steel Gary Works (Gary, IN): A tragic incident in 1991 saw

two workers fatally burned by molten steel after a ladle failure. Later,

in 2016, an electrocution led to another worker’s death, costing the

company $28,000 in fines and a stark reminder of the importance of

lockout/tagout procedures.

- Cleveland-Cliffs Burns Harbor

(Burns Harbor, IN): In 2023, OSHA cited the site for safety issues with a $5,100 fine.

And in 2020, after a worker was fatally struck by a coil tractor, the

company faced $21,000 in penalties.

These aren’t just statistics—they’re

wake-up calls. They're the reason your safety coordinator trains like a Jedi

preparing for battle. They read through manuals, memorize regulations, and

chase down hazards like bounty hunters on a mission—because when safety is an

afterthought, someone doesn’t go home.

The Jedi Safety

Checklist

Because even the Force can’t save you from a fine

|

Category

|

What to Check

|

Why It Matters (a.k.a. What Happens If You Ignore It)

|

|

PPE Ready, You Are

|

Hard hat is secure

|

Your head isn’t made of

Beskar—protect your command center.

|

|

Safety glasses on

|

Sparks, splinters, and flying screws

are not as fun in real life.

|

|

High-visibility vest/clothing

|

Forklift operators are not Jedi—they

need to see you.

|

|

Gloves appropriate to task

|

Grip like a Wookiee. Avoid band-aids

and tetanus shots.

|

|

Hearing protection in loud areas

|

Because listening to OSHA warnings

through ringing ears is ironic.

|

|

Your Work Surface Isn’t a Trap

|

OSHA Plank only—no mystery wood

|

That CDX plywood won’t catch you

when gravity strikes.

|

|

Platform is level, secure, and fully

planked

|

Jedi balance is great, but don’t

test it from 15 feet up.

|

|

Guardrails are installed where

needed

|

The Sarlacc Pit has better safety

features than some job sites.

|

|

No duct-tape fixes or improvised

supports

|

If your solution involves “just for

now,” it’s a no.

|

|

Clear of Sith-Level Hazards

|

Walkways are free of cords, nails,

debris

|

A banana peel has more comedic

timing—don’t add to the fall log.

|

|

Tools stored properly (and safely)

|

Nail guns aren’t toys. And

lightsabers don’t need cords.

|

|

Materials stacked safely

|

No one wants to play Jenga with

sheet goods.

|

|

Weather checked if working outside

|

Wind, rain, or Tatooine sandstorms

all count.

|

|

Backup Plan, You Must Have

|

First aid kit stocked and nearby

|

A little bacta box beats a full trip

to the ER.

|

|

Fire extinguisher accessible

|

Fires are for BBQs, not job sites.

|

|

Emergency contact info posted

|

Your crew needs to know who to

call—not guess.

|

|

Another trained person on site

|

Jedi don't work alone. Neither

should you.

|

|

The Force of Calumet is With You

|

Materials sourced from Calumet

Lumber

|

OSHA-approved. Jedi-approved.

Delivered fast.

|

|

Safety gear available on demand

|

We’ve got what you need, and we

speak fluent “I need it yesterday.”

|

|

Questions answered by pros

|

No droids here—just real humans

who’ve seen it all.

|

A

true Jedi doesn’t just build—they build safely. Print this checklist, slap it

on the wall, and hand it to anyone who looks like they’re about to stand on a

bucket to reach the rafters.

Final

Word: Don’t Join the Violation Side

Look, we get it—construction moves

fast. Timelines are tight, the weather's never on your side, and sometimes your

crew thinks a piece of questionable plywood and a prayer will do the job just

fine. But that kind of thinking? It's a fast track to the Dark Side. Or at

least a hefty fine and a very uncomfortable meeting with your project manager.

Staying OSHA-compliant doesn’t mean

slowing down or getting bogged down in red tape. It means keeping your people

alive, your projects on track, and your reputation intact. It’s about being the

kind of leader—or crew member—who builds with intention, confidence, and a dash

of wisdom (preferably Yoda-level, but we’ll take Obi-Wan too).

And let’s give credit where credit’s

due—your safety coordinator and safety team are the real MVPs of compliance.

They’re not just clipboard warriors or “rule enforcers.” They’re trained

professionals who have studied everything from fall protection to first

response. They stay up-to-date on OSHA regulations, lead trainings, coach the

crew, and catch small issues before they turn into catastrophic ones.

Basically, they’re Jedi Masters with high-vis vests instead of robes—and

without them, your site is just a ticking time bomb with power tools.

These folks don’t just show up when

the inspector’s around—they’re watching the job site long before OSHA steps

foot on it. They're the reason your crew knows how to properly rig a harness,

what kind of plank to use on that scaffold, and how to evacuate if something

goes sideways. If you’ve got a safety coordinator worth their salt, buy them

coffee, listen when they speak, and for the love of OSHA, stop ignoring their

memos.

And lucky for you, you don’t have to

do it alone. Calumet Lumber has your back with safety-rated materials, fast

delivery, solid advice, and zero judgment if you call us saying, “Hey, I think

we might be doing this wrong…”

So don’t be the reason OSHA shows up

with a clipboard and a stormtrooper squad. Be the Jedi who planned ahead, used

the right materials, listened to your safety team, and made the site safer for

everyone—even the guy who insists on blasting classic rock at 6:30 a.m.

Now go. Build. Lead. Respect your

safety pros. And may the compliance be with you—always.

P.S.

Thanks for indulging my Marvel and Star Wars obsession while we tackled something as thrilling as Planks and OSHA compliance. If you made it this far without rolling your eyes (or at least not too hard), you’re officially part of my Rebel Alliance. Whether you're here for the safety tips, the lumber facts, or just the dad-joke-grade puns—thanks for reading. You’re the Obi-Wan to my lumberyard.

.png)

.png)

%20397-0254%20sales@CalumetLumber.com%20www.CalumetLumber.com.jpg)

%20397-0254%20sales@CalumetLumber.com%20www.CalumetLumber.com.jpg)